The logistics and warehousing industry is entering a new era of innovation. As customer demands increase and supply chains become more complex, businesses need smarter, safer and more efficient equipment. Forklift technology is advancing rapidly, bringing new capabilities that go far beyond lifting and moving goods. For businesses exploring forklifts for sale, preparing your warehouse for the next generation of equipment is essential to staying competitive.

Toyota Material Handling Australia (TMHA) is helping operators adapt by combining advanced forklift design with data-driven technology, sustainable power options and improved operator safety. Here’s how to get your warehouse ready for the future.

1. Transition to Smart and Connected Equipment

Modern forklifts are no longer just machines – they are data-enabled tools that provide insights into fleet performance. Toyota’s I_Site fleet management system allows managers to track forklift usage, monitor safety, schedule preventative maintenance and optimise productivity.

To prepare your warehouse for smart forklifts:

- Ensure your facility has reliable Wi-Fi or cellular coverage.

- Train staff in using fleet management software.

- Develop data-driven KPIs to measure productivity and safety.

Integrating connected technology now ensures a smoother transition as forklifts become increasingly autonomous and digitally integrated.

2. Plan for Electric and Sustainable Energy Solutions

Sustainability is shaping the future of materials handling. Electric forklifts are now capable of handling demanding applications while reducing emissions, noise and operating costs. TMHA offers a broad range of battery-powered forklifts, including lithium-ion options for multi-shift operations.

Warehouses preparing for this transition should:

- Install charging infrastructure suited to lithium-ion or lead-acid systems.

- Design charging stations with safety and accessibility in mind.

- Review energy consumption to optimise operational costs.

As more businesses adopt electric solutions, choosing from Toyota’s range of forklifts for sale ensures compliance with sustainability targets without compromising performance.

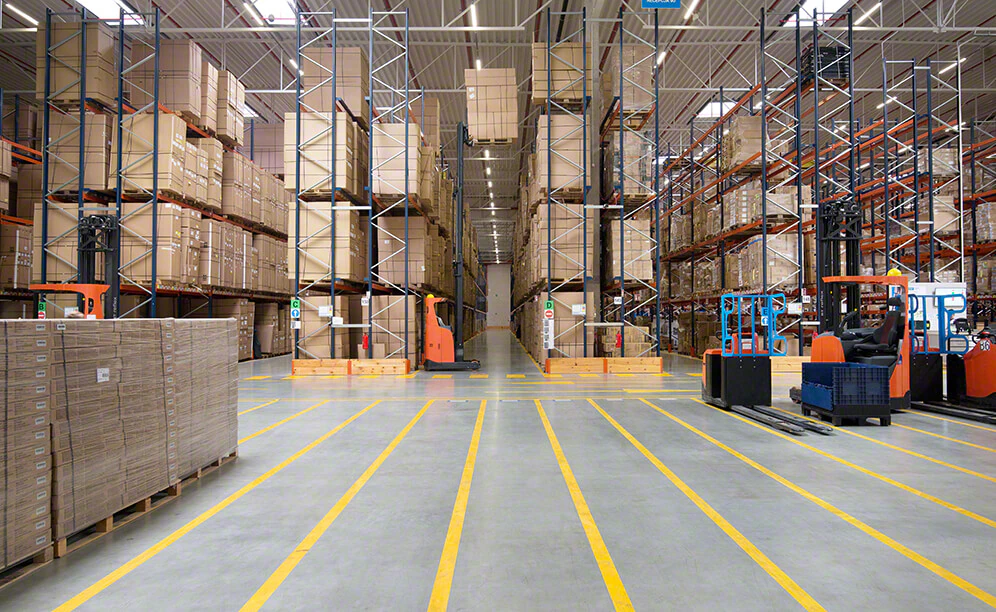

3. Redesign Warehouse Layouts for Advanced Forklifts

Next-generation forklifts, including high-reach models and narrow-aisle solutions, are designed to maximise vertical storage and improve space efficiency. To get the most from these machines, warehouses should evaluate their current layouts.

Key considerations include:

- Narrowing aisle widths to increase storage density.

- Maximising vertical racking space.

- Creating defined traffic flows for mixed equipment operation.

By preparing the warehouse layout, businesses can fully unlock the potential of modern forklift technology.

4. Prioritise Operator Training and Safety

As forklifts evolve, operators need updated skills to handle new features such as advanced ergonomics, assisted driving technologies and integrated safety systems. Toyota forklifts are designed with intuitive controls, enhanced visibility and built-in safety functions, but training remains essential.

Businesses can prepare by:

- Updating training programs to reflect new technology.

- Incorporating digital tools like pre-start checklists and impact monitoring.

- Reinforcing safety culture through regular refresher sessions.

Equipping staff with the right knowledge ensures safe and efficient use of advanced forklifts.

5. Embrace Predictive and Preventative Maintenance

With the next generation of forklifts, maintenance is shifting from reactive to predictive. Using real-time monitoring, managers can identify wear patterns and service requirements before breakdowns occur.

TMHA supports this with national service coverage and predictive maintenance options integrated into smart forklift systems. Warehouses can prepare by adopting a proactive approach to servicing schedules and leveraging data to minimise downtime.

The forklift industry is advancing rapidly, and warehouses that prepare now will benefit from improved productivity, safety and sustainability in the years to come. From connected fleet management and sustainable energy solutions to advanced safety features, the next generation of technology is reshaping the industry.

Toyota Material Handling Australia is at the forefront of this transformation, offering innovative forklifts for sale and the expertise to help businesses adapt. To explore the latest models and prepare your warehouse for the future, visit Toyota Material Handling today.