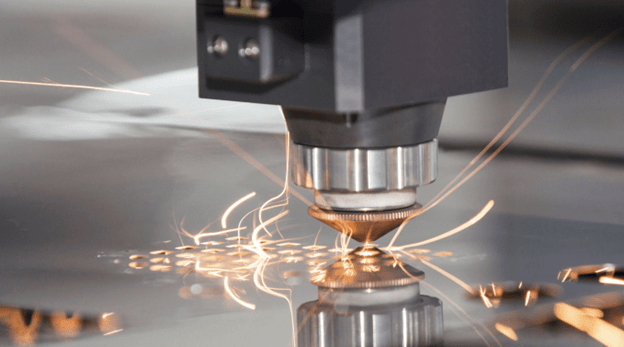

When you picture laser welding, you probably imagine a bright beam melting metal with perfect precision. But behind every successful weld lies an entire ecosystem of invisible systems working overtime. Cooling units, optical pathways, dust control mechanisms, and air filtration setups all operate quietly in the background to support the performance of a laser welder.

If you’re using laser welder technology for fabrication, repair, or continuous industrial production, understanding this hidden infrastructure isn’t optional—it’s essential. The quality of your welds, the longevity of your equipment, and the safety of your workspace depend on far more than just the beam itself.

The Thermal Challenge: Why Cooling Is Critical in Laser Welding

Sources of Waste Heat in Laser Systems

Although laser welding feels incredibly efficient, every laser system generates significant waste heat. Only a portion of electrical input becomes usable laser energy—often just 30–40%. The rest becomes heat that accumulates in the power source, optics, and internal components.

Left unmanaged, this heat causes power instability, wavelength drift, and premature component failure, making a robust cooling strategy essential.

Types of Cooling Systems Used

Cooling solutions vary widely depending on the power rating and duty cycle:

- Water-cooled systems — provide superior heat removal for medium and high-power welders.

- Air-cooled systems — used in lower-power or portable units where mobility matters.

- Hybrid cooling setups — combine both methods for balanced performance.

Each cooling system is designed to keep thermal loads stable during long welds, repetitive cycles, or high-penetration applications.

Impact of Cooling on Welding Quality and Longevity

A controlled thermal environment ensures:

- Stable power output

- Consistent penetration and weld integrity

- Protection of lenses, mirrors, and diodes

- Longer equipment life

Even minor temperature fluctuations can change your beam’s properties, making consistent cooling a direct contributor to weld quality.

Cooling System Best Practices

A reliable cooling setup requires proactive care:

- Use the correct coolant (often deionized water or water-glycol mix).

- Clean filters and heat exchangers regularly.

- Check coolant purity to prevent corrosion or deposits.

- Monitor flow rate and pump performance.

A cooling system is the “heart” of your welding setup—if it fails, everything else follows.

Optics: The Hidden Pathway of Light

Why Optics Matter So Much

Your laser welder relies on pristine optical components to shape, focus, and deliver energy accurately. Any contamination or damage—no matter how small—can:

- Scatter the beam

- Reduce penetration

- Cause inconsistent fusion

- Trigger dangerous reflections

Clean, aligned optics are what keep your welds predictable and strong.

Environmental Vulnerabilities

The environment around a welding station contains vaporized metal, particulates, and fumes—all of which settle on optical surfaces if left uncontrolled. Over time, this buildup leads to:

- Lens fogging

- Reduced beam quality

- Thermal stress cracking

- Unexpected shutdowns

Optical degradation often happens slowly and invisibly—until the weld quality suddenly drops.

Maintaining Optical Integrity

To keep your optics performing, you should:

- Clean lenses gently with approved wipes

- Replace damaged optics immediately

- Keep optical compartments sealed

- Maintain stable humidity and temperature

- Use purged optical enclosures when possible

Simply put: clean optics equal clean welds.

Dust, Fume, and Particulate Management

Understanding Welding Emissions

Laser welding vaporizes metal rapidly, generating fumes, smoke, and ultrafine particulates. Depending on your materials, this plume may include:

- Metal oxides

- Volatile organic compounds

- Toxic compounds

- Sub-micron dust

Welding coated, painted, plated, or galvanized materials increases the danger and volume of emissions.

Why Dust Control Matters

Poor air control affects two critical areas:

- Human health — inhalation of metal particulates can cause respiratory, neurological, and systemic harm.

- Machine performance — dust deposits reduce optical clarity and compromise weld quality.

Uncontrolled fumes also lead to regulatory issues and reduced operator comfort.

Dust and Fume Extraction Solutions

An effective extraction setup can include:

- Source-capture fume arms

- Local exhaust ventilation

- Back-draft or downdraft tables

- HEPA-filtration dust collectors

- Sealed enclosures with airflow design

The goal is the same: keep emissions away from operators and equipment.

Best Practices for Air Quality Safety

For a clean, safe environment:

- Replace filters on schedule

- Monitor air quality during extended welding

- Keep welding zones separate from offices

- Use PPE (respirators) when needed

- Ensure airflow is properly directed and unobstructed

Air quality is not a “nice-to-have”—it is a core part of your welding ecosystem.

Designing a Holistic Laser Welding Infrastructure

Why Systems Must Work Together

Cooling, optics, and dust control are not independent. They form a tightly connected ecosystem:

- Poor cooling causes optics to overheat

- Dirty optics increase the required power and generate more heat

- Dust contamination accelerates optical degradation

If one subsystem is weak, the entire weld setup suffers.

Engineering Considerations

When planning or upgrading your shop:

- Choose cooling based on your duty cycle and output

- Design ventilation before installing your welder

- Make maintenance access as easy as possible

- Keep welding cells isolated for cleanliness and safety

A well-designed environment directly improves weld consistency and machine lifespan.

Implications for Modern Laser Welding Users

Performance Consistency

A fully supported infrastructure delivers stable power, repeatable welds, and minimal downtime.

Safety and Worker Health

Clean air, controlled radiation, and safe operating environments protect both operators and equipment.

Cost Efficiency and Longevity

Preventive care reduces repairs, extends lifespan, and prevents costly system failures.

Using the Right Tools: The Role of a Modern Laser Welder

As you scale your welding operation, having equipment built for stability, heat control, and clean operation matters. This is where a professional-grade laser welder can make a difference. Systems designed for industrial environments integrate engineered cooling, optical protection, and built-in dust mitigation features, helping you maintain reliability even in demanding conditions.

With a setup engineered for durability and controlled performance by Denaliweld, you’re able to weld longer, safer, and with greater consistency—no matter your workload.

Conclusion

A laser welding system is much more than the bright beam you see on the surface. Cooling loops, optical pathways, airflow systems, and dust management infrastructure all operate silently to keep that beam stable and safe. If you want clean welds, reliable uptime, and long equipment life, these hidden elements matter as much as the laser itself.

By understanding and maintaining this infrastructure—and by using reliable, well-engineered equipment—you can ensure that your laser welding operations remain efficient, safe, and built for long-term performance.